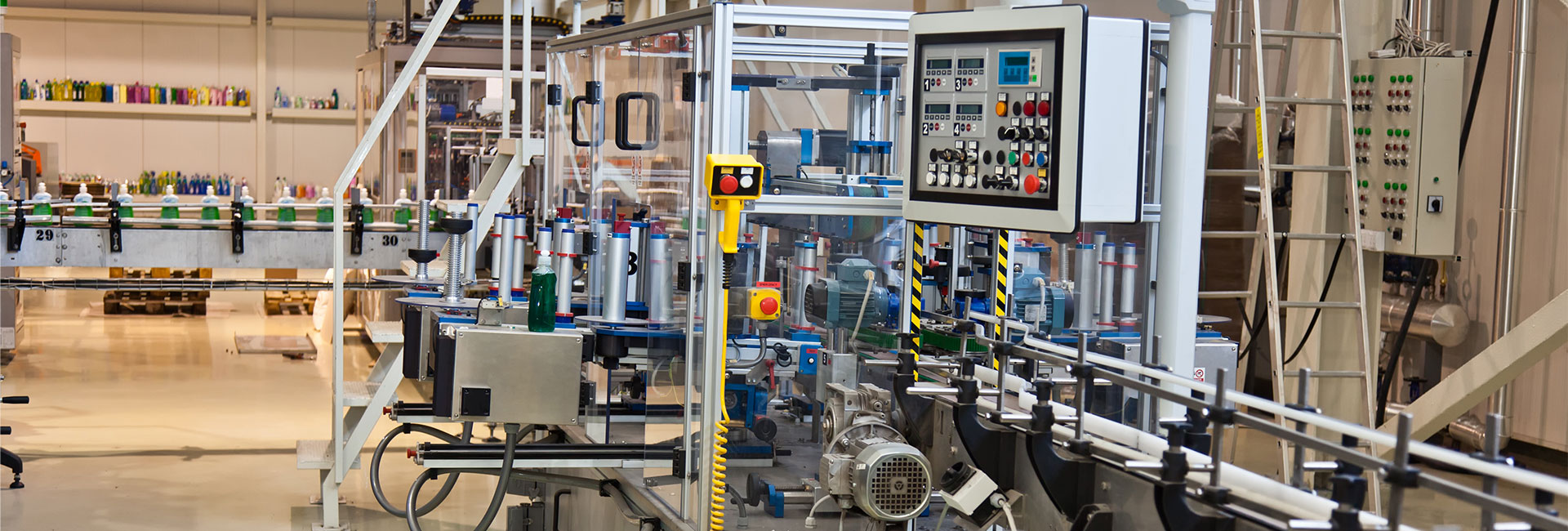

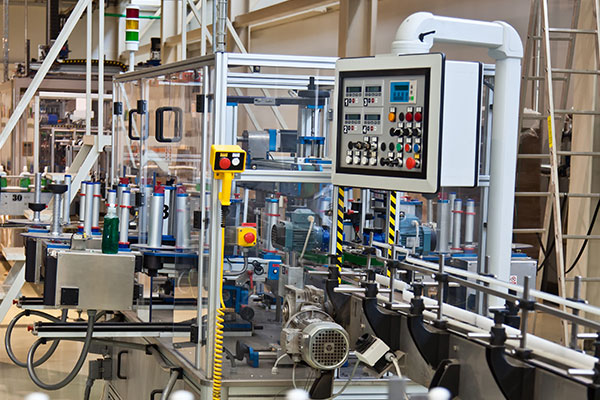

Efficiency Analysis

Based upon mathematical calculations, we will advise you in what to replace, upgrade, or change lines, through analysis of existing packaging lines, and operations to review the efficiency of each machine. Our goal is to help you reduce costs, increase throughput, and reduce manpower.

There are three areas that contribute to the efficacy of a packaging line or any other complex manufacturing process.

The first is equipment. We will review the age of the equipment, the robustness, the appropriateness of the machine in relation to the product, and the long term maintenance of the equipment, we can help you decide what direction to pursue, be it a new machine or an upgrade.

The second area is the operator. The skill level of operators and mechanics can significantly influence the efficiency of the packaging line. Knowledge of the equipment and the level reaction to any issues that come up during production is paramount. This review includes looking at the ability of the mechanics to repair and get machines up and running during a failure, the training of the operator, and the level of availability of spare parts.

The last item that is taken into account is the component input to the packaging line. If the components are not used within specifications when introducing them to the line, this can dramatically affect the way the machinery operates. This can significantly impact the overall efficiency of the line.

When we analyze each of these areas, we can identify which piece is affecting the throughput of the line, or if there is a synergistic effect occurring due to overlap between the components. Keep in mind, the more efficient we can become, the more a packaging line reduces the “cost of the bottle in the box”.

If you're interested in our Efficiency Analysis Service, please call us at (215) 249-3454 or fill out our contact form.

← Back to Services Page