Model CVC1205, Capper

April 23, 2021

Model CVC700, Loading and Accumulation Turntable

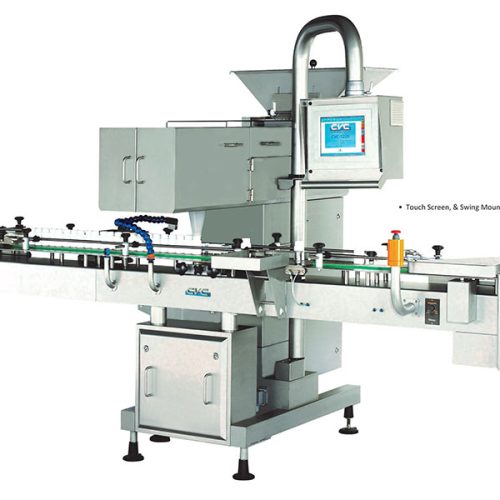

April 23, 2021Model CVC1208, Retorquer

The CVC1208 Retorquer is designed to retighten screw-on caps after induction sealing at speeds of up to 120 bottles per minute. The 1208 is PLC controlled and comes standard with a 6″ Touch Screen terminal. Options include tower lamp, servo torque metering, reject, and reject verification.

- Built to cGMP Standards

- Stainless Steel Construction

- 10 Channels of Memory

- Quick & Easy Change Over

Request Product Updates

Category: Nutraceutical and Pharmaceutical Packaging

Tag: CVC

Standard Features

- PLC Controlled

- 6″ Touch Screen Panel to access all settings

- Stainless Steel Construction

- Memory capacity for 10 jobs

- Cap Tightening Station with 1 set of spindles

- Capacity: up to 120 Bottles per minute (BPM)

- ISO 9001:2000 Certified

Container Specifications

| Cap Height | 3/8 to 3/4 in 10 to 20 mm |

| Cap Diameter | 1-1/8 to 4-3/8 in 28 to 111 mm |

| Bottle Height | 2 to 8 in 50 to 200 mm |

| Bottle Diameter | 1-1/8 to 4-3/4 in 28 to 118 mm |

Machine Specifications

| Machine Weight | 728 lbs 330 kg |

| Noise Level | 75 dB |

Air/Electrical Requirements

| Power | 220 V |

| Frequency | 50/60 Hz |

| Phase | Single |

| Power Consumption | 3 A |

| Minimum Air Pressure Minimum Air Pressure ISO 8573-1 |

87 psi |

| Air Consumption Air Consumption With rejection |

3 ft³/min |

Available Options

| Conveyor Belt Width Conveyor Belt Width Motorized Sanitary Conveyor, 4-1/2″ wide belt standard (6″ wide belt available) |

4-1/2 in (Standard) 6 in (Optional) |

Rejection System

Rejection verification check

Torque Metering (servo motor)

Tower lamp

TST with OPC Code Software (21 CFR Part 11)

Specification Notes

| Note | Dimensions shown are for a standard machine. This machine can run independently or can be integrated into an automated packaging line. All CVC equipment is covered by a one year parts warranty. Full Warranty details are included in our equipment proposals or can be found on our website. |